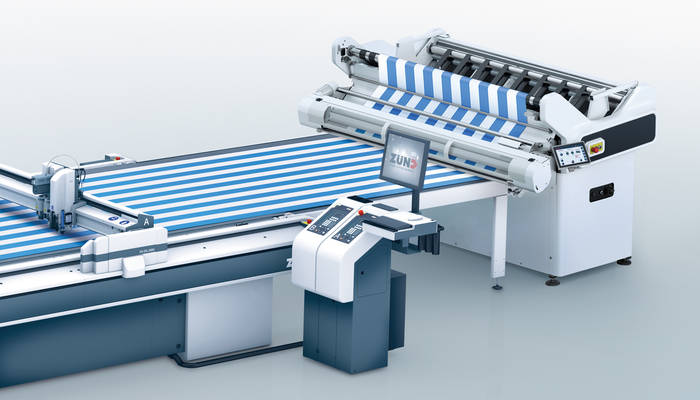

Zünd has further developed its tub dispenser and made it even smarter with new functions. With the integrated cross cutter, intelligent control and smart material transport, the new 100 tub unwinder offers a high degree of automation and maximum efficiency in textile cutting.

Like its extremely successful predecessor launched in 2017, the Tub Unwinder 100 unwinds stretchable textiles without distortion or tension. The integrated material feed control continuously monitors the material feed to the cutter and regulates it even more precisely than its predecessor.

The heart of the advanced roller transport system is the optional, integrated cross cutter. It cuts the textile web at the end of the marker while the cutter is still busy cutting the parts. This means that the textile roll can be changed while production is running and thus the next job can already be prepared. The result is drastically reduced set-up times, especially for users who frequently process short markers. The cut-off can either be triggered manually by the operator or automatically by the cutter software.

The control system has also been further developed, both ergonomically and technologically. This includes an enlarged touch display and the tub unwinder can now be operated from both sides. Furthermore, the corresponding parameters for different textiles can now be preset, saved and managed.

For ergonomic loading, the tub unwinder 100 has the option of lowering one leg of the tub. During material transport, a dancer roller continuously registers fluctuations in the web tension. If necessary, the tub unwinder automatically regulates the feed speed. This is also synchronised with the cutter, which further minimises material tension and distortion. The tub unwinder can not only unwind material rolls, but also roll them up. This means that fabric webs can be easily rewound after the end of production. Tight winding results in compact textile rolls for easy storage.

As with its predecessor, the Tub Unwinder 100 is loaded with textile rolls weighing up to 100 kg via the tub. This is now equipped with twice as many conveyor belts and thus ensures optimised unwinding behaviour.

For even more flexibility, for example with statically loaded, "sticky" textiles, there is an optional unwinding unit with core support, with which the tub unwinder can be upgraded if required. The tub unwinder 100 is available immediately for the S3, G3 and D3 cutter series (table widths 1800, 2270 and 3210 mm).

www.zund.com