By David Lee, Focus Label

Serigraphy is the artists' term for silk screen printing, a process which involves a stencil and ink which is forced through a silk screen, although modern versions are often made of nylon or finely woven polyester. One colour is applied at a time and a blade is used to sweep the ink smoothly across the press.

Serigraphy is an extremely ancient form of printing and has been used since the days of the Chinese Song Dynasty (960 - 1279 CE) to transfer exquisite designs to silk material. In modern times, machine-based heat transfer silkscreen printing is used in the textile industry to mass produce attractive prints on fabrics, including t-shirts, curtains, cushion covers and bed linen. Heat transfer is also a popular alternative to sew-in garment labels, especially for underwear and swimming costumes.

Modern Serigraphy Is A Two-Stage Process:

1) Graphics and text are printed onto heat release paper, appearing as a mirror image.

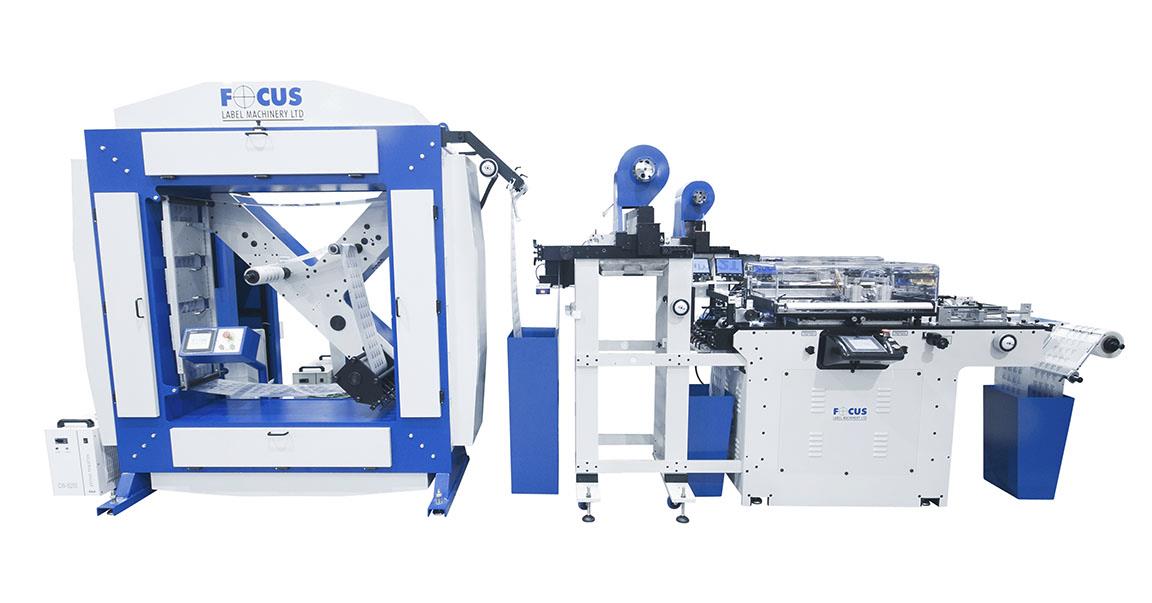

2) The images are transferred to the fabric substrate by means of a specialised heat transfer press, such as our Focus Labels TagTrans series.

Advantages & Disadvantages

One of the reasons silk screen printing has stood the test of time is it is an extremely cost-effective way of printing large quantities of fabric, as well as being low in waste and relatively easy to produce consistently high-quality results, especially when working with dark fabrics. It allows you to deposit a larger volume of ink while retaining good opacity and colour strength.

A disadvantage of silkscreen heat transfer label printing is that only one colour can be printed at a time, and each layer of colour needs drying time before the subsequent colour can be applied. This makes it comparatively slow for complex and multi-coloured designs, the result being that the transfer is normally only used for one or two colour designs. Silkscreen printing can also result in a high proportion of rejects caused by registration issues between colours.

We have overcome many of these disadvantages through our patented Heat Transfer Label Printing Method (TagTrans), which can be used with our LX Letterpress rotary presses and stand-alone silkscreen printing systems. TagTrans allows roll-to-roll, multi-coloured printing and increases the speed and versatility of heat transfers while reducing print errors and wastage. To increase opacity on darker fabrics, the image can be overprinted with an opaque white silk screen ink, which sits in perfect registration with the original design.

Improvements in silkscreen heat transfer technology have made specialised presses more cost-effective and reliable, and make heat transfer an economically viable alternative to textile ribbon printing for some projects.

www.focuslabel.com