Visual communication is quite varied: From signage to wall graphics, giant posters, vehicle wrapping, to POS material and much more. A project can often comprise of a wide variety of large format print products produced on a range of machines, a combination of materials and finished in a number of differnet ways.

OneVision Software (at booth K12) provides reliable, powerful and flexible software which can automate these processes, cutting production time and increasing profitability.

Regensburg/Birmingham. Now more than ever, with the challenges posed since March 2020, print businesses need to seek ways on improving automation, turnaround times and margins to ensure they have a sustainable business. One prepared for growth as things begin to return to a ‘new normal’. With more than 25 years of experience, software manufacturer OneVision and its automation software supports print service providers successfully in this transformation.

Workflow automation from prepress to press onto embellishment and finishing

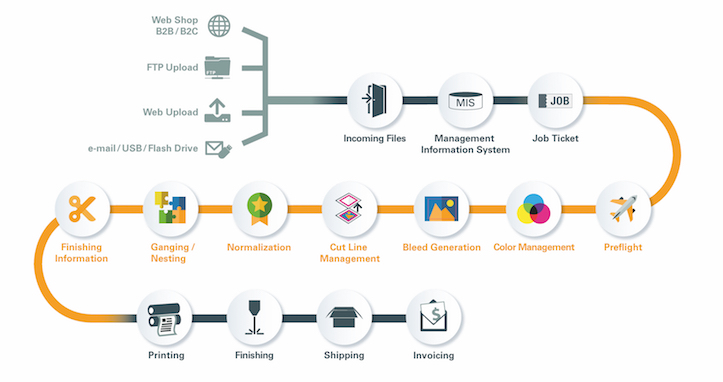

As a so-called middleware, OneVision's automation software allows print service providers to implement a holistic end-to-end workflow starting from the file input to the production stage. The basis of the software is an extremely flexible, easy-to-use workflow management system that can be connected easily to other parts of the system landscape (e.g. MIS, web-storefront and DFE). Through the seamless integration, print files pass through classic file preparation steps (e.g. preflighting, color management, flattening of transparencies, etc.) via defined workflows. In addition, tools specially tailored to the needs of wide format, commercial or screen printers – such as nesting, tiling and paneling, creating cut lines, generating bleed etc. – automatically prepare files for the printing and finishing process. The software then transfers the required production files to printing machines and post press systems.

High performance printing for more throughput and reduced substrate costs

As a result, printing businesses benefit from shorter make-ready and production times, a more efficient use of substrate and an overall increased profitability. Customer-focused cooperation with renowned press and finishing system manufacturers (e.g. Canon, EFI, Zünd, …) allow an optimal interplay of software and hardware.

www.onevision.com