Whenever satellites are traveling in space, there’s a good chance high-precision cutting technology from Swiss cutter manufacturer Zünd helped make it happen. Technology company Thales Alenia Space (TAS), an important player in the aerospace industry, uses various composites and other synthetic materials for the construction of satellites, space probes, and spacecraft. For cutting these composites, Thales Alenia Space relies on digital flatbed cutting systems from Zünd.

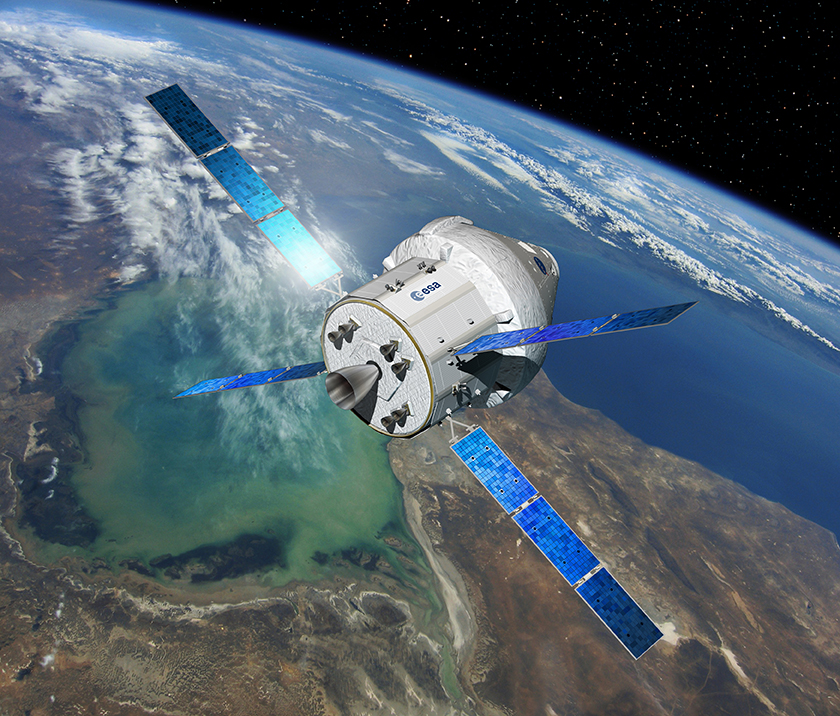

Thales Alenia Space, a joint venture of Thales Group and Leonardo, develops and builds aerospace systems in partnership with agencies such as the European Space Agency (ESA) and NASA. The company has some 9,000 employees at 17 locations in Europe and the US. The Galileo satellite navigation system, the Italian satellite program COSMO-SkyMed, and the Orion MPCV spacecraft are among the best-known projects in which Thales Alenia Space plays a central role alongside ESA and NASA.

One of Thales Alenia Space’s core competencies is manufacturing structures made of composite materials. These structures are used in spacecraft components such as fuselage panels, support structures, antenna mounts, solar panels, cladding, and fuel tanks. Because of the extreme conditions in space, structures used in spacecraft have to be exceptionally strong, lightweight, and robust. “Our components are used in the service module, for example, which provides propulsion and climate control in addition to supplying electricity, water, and air,” explains Tiziano Pegorin, Director of the Center of Competence for the Manufacture of Space Infrastructures and Modules in Turin, Italy. To ensure the custom-built structures meet the exacting requirements associated with space, cutting precision and quality are of the utmost importance.

Prior to Thales Alenia Space investing in Zünd technology, the cutting of composites was outsourced. This often resulted in delivery delays and issues in the production process. Besides precision cutting and adherence to the highest quality standards, a short time-to-market is yet another critical success factor. That is why in 2022, Thales Alenia Space decided to integrate cutting in its internal production workflow and invested in a Zünd G3 cutter. This brought control over the cutting process back in-house and significantly reduced overall production times, explains Structure Manufacturing Manager Roberto Milani: “Zünd cutters are strategic allies for any company that wants to make its production more efficient and transition to lean manufacturing without compromising flexibility, precision, and quality.”

The Zünd G3 XL-3200 cutter is equipped with a special protection system for composites, which shields the electrical components against potential short circuits carbon fibers may cause. An Integrated Tool Initialization system ensures the correct processing depth for every material and every tool. The Zünd cutter is exceptionally versatile. Various tools can be used depending on the material. These include the Pneumatic Oscillating Tool – POT, ideal for honeycomb and other thick materials, or the Universal Cutting Tool – UCT with a fixed tangential blade that offers fast, precise cutting of thin materials. The RM-A routing module is used for routing rigid honeycomb materials, aluminum, and ablative materials.

Andrea Giannitti, Director of the Composite Material Technologies and Processes Department, points to the extensive material database with ideal cutting parameters for countless materials, which can be adapted individually as needed. “At Thales Alenia Space, every process is certified. For each one, we have created ‘recipes’ that are saved in the ZCC Zünd Cut Center operating software. Our operators can access them quickly and easily, allowing them to flawlessly repeat cutting processes. Another notable feature is the nesting function. For example, we can nest additional components on remnants while cutting is still in progress, which reduces both waste and idle times to a minimum.

One project that showcases the benefits of Zünd’s digital cutting technology is the satellite that was constructed for ESA’s Mars Sample Return Mission. A key component of the satellite intended to collect material samples on Mars is a cone-shaped funnel with an exterior layer of carbon fiber applied over sandwich panels. The carbon-fiber layer consists of various sections whose fiber orientations must be precisely aligned with each other. “Cutting these parts manually, with the correct fiber orientation and optimum material utilization, would be impossible. The Zünd cutter enables us to make prepreg part kits much more quickly.” TAS is also continuously testing the use of new materials cut using the Zünd cutter. “Recently we were experimenting with natural cork for the lining of re-entry vehicles. Once again, the results met our requirements,” reports Giannitti.

Thales Alenia Space was already familiar with the quality of Zünd cutters. An identical cutting system has been in use at the TAS plant in Cannes, France, since 2021, and has become an indispensable part of the company's cutting operations. Today, TAS benefits from the knowledge transfer and synergies that the use of identical production equipment at various locations can bring.

www.zund.com