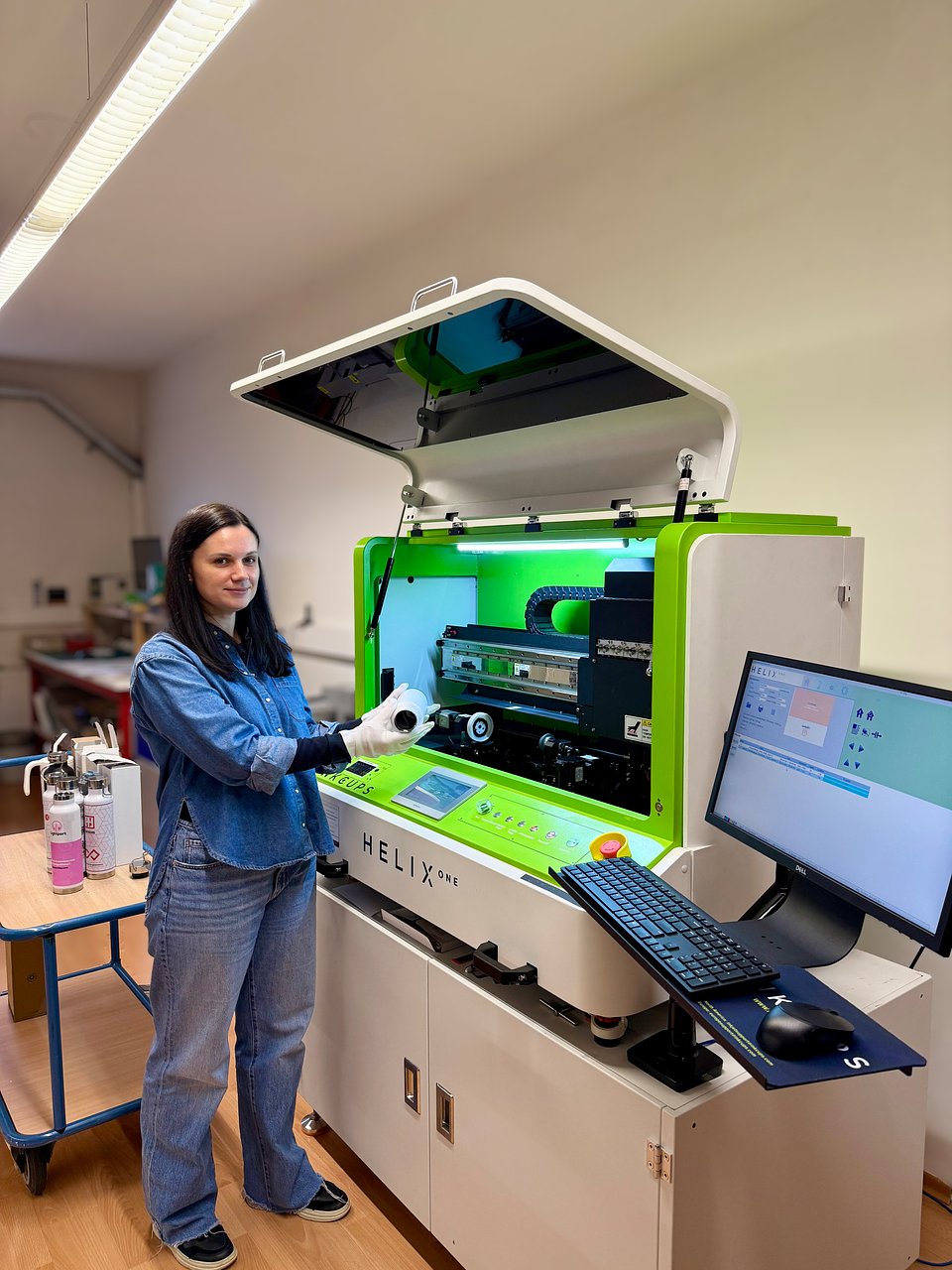

Austrian design and print company, Koller Media, recently tapped into the possibilities within direct-to-object cylindrical printing and capitalised on growing demand for personalisation in Austria with investment in an Inkcups Helix ONE®.

Koller Media was founded in 1995 by Robert Koller after he completed his training as a prepress technician and typographer, taking over a typography and repro studio in Salzburg. Three decades later, Koller Media has grown to become so much more than just a print service provider, priding itself on flexibility, state-of-the-art production methods, and the use of a vast range of materials for customised, sustainable, and economical production. As a result, Koller Media has established itself as a complete printing partner for customised solutions with a broad customer base ranging from individual graphic designers and agencies to larger marketing companies, food and beverage manufacturers, tourism, fashion, construction, craftsmen, and small manufacturers.

Made up of five team members, Koller Media operates from a 400m2 site situated 20 km north of Salzburg in the “Silent Night” Municipality of Lamprechtshausen, located in the Arnsdorf district. The company doesn’t just focus on technical and digital capabilities, but also on ideas and perfect design for a truly unique product - something that is more important than ever as demand for customisation and personalisation rises. “We not only offer excellent advice, but also tailored solutions and creative product design. From ‘Pimp my Print’ to design and the finished product, we take on every challenge,” Robert explains.

A Shift Towards Smaller Quantities and Unique Products

Areas that Koller Media has seen growth in are customised packaging, labels, and print embellishments and in turn, the company has experienced a shift towards smaller quantities and desire for unique products. According to Robert, high-quality print products on natural papers that stand out from standard and mass produced goods are the most popular for the business. With a passion for packaging and design and always on the look out for alternative solutions that fit Koller Media’s business model, Robert’s interest was piqued when reading about the possibilities of industrial cylindrical printing. Having read a customer story detailing how personalised gift producer Proper Goose tapped into the opportunities within direct-to-object personalisation by investing in Inkcups Helix® technology, leading to the formation of a new trade arm, Bottled Goose, Robert recognised an opportunity to capitalise on this lucrative area of the market.

“The chance to expand our offerings with something completely new and to market our own product designs led me to search for suitable entry-level solutions,” Robert explains. After making contact with Mario Münzner, Sales Representative Europe Central at Inkcups in late 2023, Robert attended an initial demo for the Helix ONE® at FESPA Amsterdam in March 2024, meeting again at Drupa in Düsseldorf in May 2024. After seeing the machine in action and forming a strong partnership with Mario, Robert was convinced by the print quality speed, user-friendliness, additional capabilities like white ink and varnish, and the machine’s compact design. “It was also important to me to work with an experienced manufacturer and have scalability options,” Robert explains.

The machine was installed in mid-October 2024, and despite having no prior experience with cylindrical digital printing, Koller Media had several orders waiting right after setup and training, having communicated this new offering to selected customers. By mid-December the company had completed its first 1,000 orders using various bottle materials including metal, glass, and plastic for a variety of customers. “This was an intensive but invaluable learning phase where we gained lots of experience,” says Robert. “The biggest challenge was creating the tooling for various bottles, and Inkcups provided excellent support for the initial orders. They also provided information and a range of primers to perform sufficient testing.”

Now, Koller Media is focused on broadening this potential that investment in direct-to-object cylindrical printing brings and has already produced 600 water bottles in various styles, pre-treated to be dishwasher safe; various metal and plastic thermal bottles; and candles using the Helix ONE®.

Entering New Markets and Winning New Orders

Koller Media is the first company in Austria to invest in an Inkcups machine, reflecting the growing demand in Europe for personalised cylindrical products. For Koller Media, the investment in direct-to-object cylindrical printing was somewhat of a leap of faith as despite growing demand, the company didn’t have any products in its portfolio or enquiries for this type of product prior to making the purchase. However, Robert explains that it was the price point, compact design, and Inkcups’ experience that were the unique selling points that made the Helix ONE® the right choice for Koller Media.

With the full capabilities of the Helix ONE® still to be explored, Robert is particularly excited about further applications such as conical cups and personalized drinkware. With extensive experience with graphic software components, Robert particularly enjoys the intuitive operation and practical data preparation capabilities of the Helix ONE®.

On how the cylindrical direct-to-object printing capability has enabled Koller Media to enter new markets, Robert says: “We’ve convinced existing customers, who have provided great feedback and showed significant interest. We’ve also processed enquiries from new market segments, which are progressing well and we plan to build on this momentum. Currently, it has generated significant attention, interest, and initial orders, and I remain optimistic and see this as a positive step. The Helix ONE® is a great entry point into this market in Austria.”

www.inkcups.com