Epson has developed inkjet technology to enable uniform printing of organic light-emitting diode (OLED) displays that brings the launch of next-generation big-screen TVs closer to reality. Overcoming the uneven distribution of the organic materials was the last major obstacle hindering the production process; now the only tasks remaining are improving the lifetime of the materials and lowering production costs.

There are several reasons why many in the display industry are eagerly anticipating the launch of large OLED panels, says Satoru Miyashita, General Manager of Epson's Production Engineering Center. Unlike the inert liquid crystals that form the images on LCDs, the organic materials of OLED displays emit light directly when an electric current is passed through them. „So there is no need for expensive backlighting like in LCDs," says Miyashita. „This significantly reduces the components cost of making the display. And, just as importantly in this era of concern over the environment, it cuts energy consumption to roughly one-third that of LCDs and to a mere one-tenth that of plasma displays." Miyashita lists other advantages inherent to the technology, including a far thinner and simpler structure to fabricate; superior picture contrast and resolution; richer, deeper reds, greens, and blues; and a wide viewing angle. Together, these advantages make OLED technology ideal for home-theater TVs.

Miyashita lists other advantages inherent to the technology, including a far thinner and simpler structure to fabricate; superior picture contrast and resolution; richer, deeper reds, greens, and blues; and a wide viewing angle. Together, these advantages make OLED technology ideal for home-theater TVs.

Inkjet innovation

So why don't these displays already dominate the industry? Currently, they can be found competing in market segments like mobile phones and digital cameras–small-screen applications that do not require displays to be switched on for hours at a time. The material used to make these OLED displays is known as small-molecule organic material, and it is applied by using a mechanical patterning process called vapor deposition, which is similar to spraying paint over a pattern plate.

"Vapor deposition works when producing small and medium-sized displays, but it is impractical and too expensive for large displays," says Miyashita. „Production costs and the cost of masks rise greatly as you increase the size of the panel, and you also run into problems like shape distortion of the larger masks during the manufacturing process."

For these reasons Epson has been leveraging its extensive experience with inkjet technology in seeking to fabricate larger OLED displays. In general, the inkjet process employs polymer organic materials that can be turned into liquids with the help of solvents. In liquid form the organic materials can be printed in layers directly onto the substrate of a display.

"Inkjet printing has a number of advantages over the conventional process," says Miyashita. „For instance, you don't need large vacuum deposition equipment; it makes more efficient use of the material–80-percent usage compared to around 10 percent by vapor deposition; and printing OLEDs requires fewer process steps."

The type of inkjet head Epson uses to apply the organic material is called a multilayer piezo head, which is able to meet the exacting requirements of this kind of printing. When a voltage is applied to the piezo head, it triggers actuators that jet out ink through nozzles in precisely measured droplets and with great speed and accuracy. The specifications are impressive. In one second the micro piezo head deposits up to 60,000 droplets as small as 1.5 picoliters (trillionths of a liter) in a target area measuring just 8 microns (millionths of a meter) in diameter.

This printing method is also highly adaptable. It can be used with a broad choice of ink solvents, such as water, thermoplastic resin, and organic solvents to accommodate a range of ink solutions, including pigment and dyes, ceramics, and nanoparticles, besides the polymer solutions employed to print OLED displays. Such flexibility makes the method suitable for a variety of applications in both personal and office printing, as well as in commercial and industrial printing. Examples of the latter include the fabrication of color filters for LCD panels, the production of metal bonding in semiconductor packaging, and the formation of the alignment layer used in LCD panels.By contrast, Miyashita says the thermal method of inkjet printing favored by competitors is less flexible when it comes to choice of inks and solvents. And because the ink must be heated to a very high temperature during application, it is less suitable for applying organic materials.

Smooth Distribution

Nevertheless, micro piezo printing, as with all forms of inkjet printing, is faced with the problem of variation in the thickness of the ink film–technically known as mura. „No matter how precisely we engineer the print head, ink volume will differ ever so slightly from nozzle to nozzle," says Miyashita. The result is dark bands visible to the human eye.

Printer manufacturers use several rather complicated methods to overcome mura that involve either having the print-head pass over the application area a number of times to even out ink distribution or relying on an algorithm to adjust the print-head position as it makes several passes over the application area.

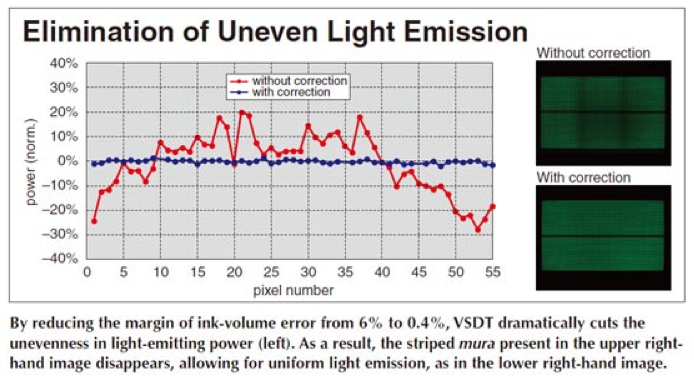

"But we were able to use a really simple method to deal with mura," says Miyashita. His researchers measured the shape and height of each polymer droplet jetted from each nozzle. This gave them the data needed to adjust the droplet volume for each nozzle to ensure even printing. The adjustment is made by means of Epson's original VSDT (variable-sized droplet technology). VSDT allows Epson to decide which of three different sizes of droplet–small, medium or large–a given nozzle will jet at any given moment. Control of the droplet size is achieved by programming the electronic driver signals sent to the individual print-head actuators.

"When using VSDT the change is dramatic," says Miyashita. „Without it, ink-volume error varies by 6 percent. After compensating with VSDT, ink-volume error is just 0.4 percent, which results in uniform light emission."

The researchers employed the improved printing method to fabricate a 14-inch OLED panel with characteristics equivalent to a 37-inch full high-definition panel (1920 × 1080 pixels).

With the problem of mura overcome, Epson is now working with chemical manufacturers to improve the lifetime of OLED materials. "Only the lifetime of blue OLED material remains short," says Miyashita. „But it is being extended threefold annually, so I anticipate this issue to be resolved by next year and would expect to see the mass production of large OLED TVs begin around 2012."

Meanwhile, Epson says it is exploring all possibilities for utilizing the fabrication technology to make big-screen OLED TVs a reality in the near future.