Leading manufacturer and supplier of banner finishing and textile finishing solutions, PLASTGrommet will demonstrate the power of finishing automation through its range of technologies at FESPA Berlin on Stand B50, Hall 27. The company will also launch four new solutions to the market.

Bringing banner finishing to entry-level, the All In One EDGE will launch at the show. Offering the same integrated welding, eyeleting, and cutting capabilities as the popular All In One banner finishing machine, which is used by multiple online printers for their banner finishing, the All In One EDGE is aimed at medium-sized companies at a fraction of the cost.

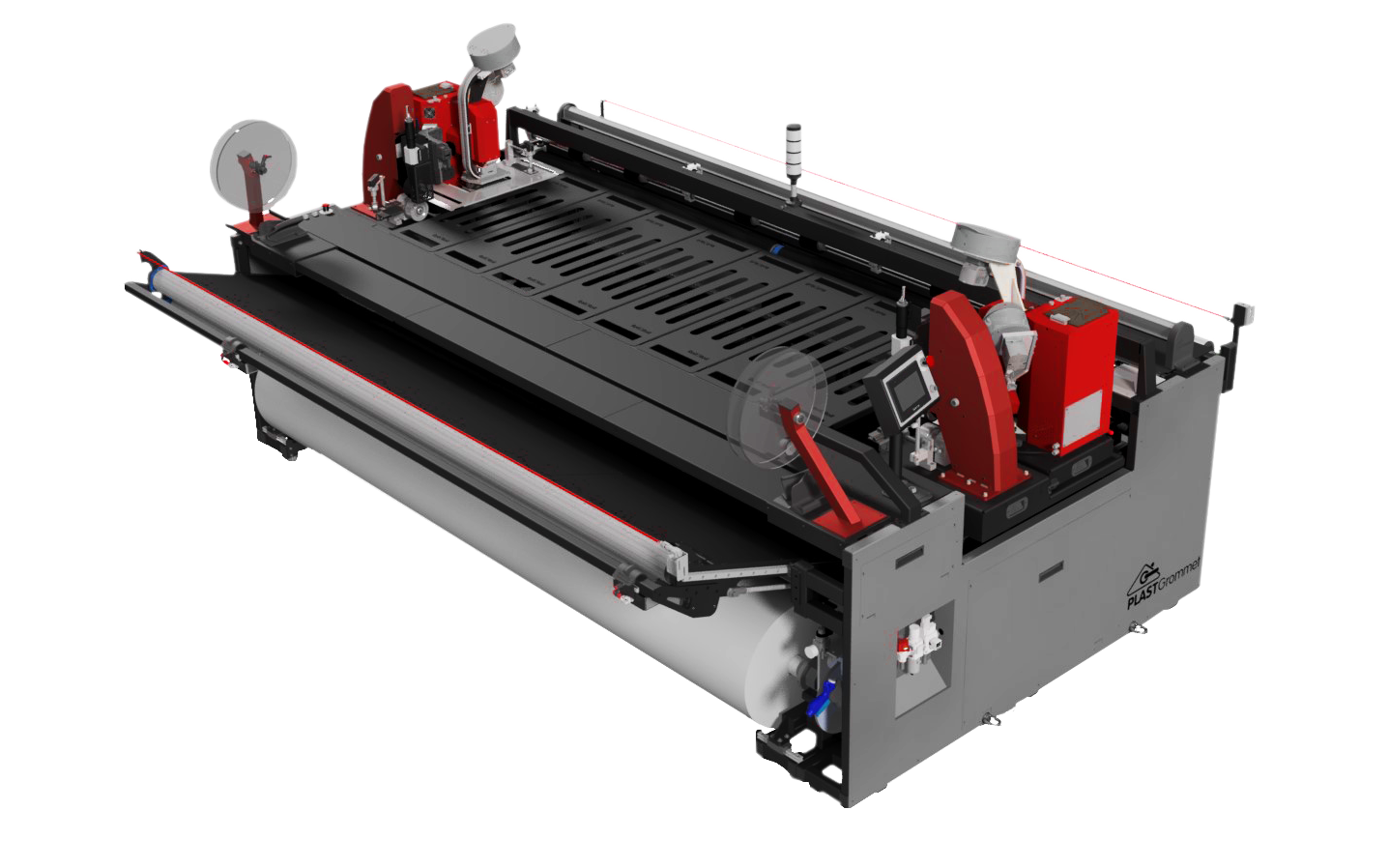

Utilising the All In One platform, PLASTGrommet will demonstrate new sewing automation capabilities for textile finishing, in the form of the TexWiz. By adding a sewing module to the All In One, the PLASTGrommet team will showcase how to automate the production of air mesh fabric banners throughout the event.

Additionally, PLASTGrommet will introduce a new innovative solution, the Winder360, designed to automatically rewind banners from the All In One, creating efficient workflow that ends with other products in PLASTGrommet’s portfolio including the Evolve Welder, the Autocross automatic eyelet press, or the Finishing Station. By integrating with the All In One, the Winder360 reduces the time required to finish the short sides of banners by 50%.

PLASTGrommet will also launch a new media roll lifter for Jumbo rolls in the form of the JumboMAX 1,000kg.

In addition to these new solutions, PLASTGrommet will showcase a range of products for banner finishing, eyelet equipment and in-house-manufactured proprietary clear plastic and metal eyelets, as well as media roll lifters, providing finishing and automation solutions for businesses of all sizes.

Banner Finishing Solutions:

● All In One EDGE, an entry-level in-line finishing system for medium-sized companies.

● All In One in-line system for automating banner finishing by integrating into a single process welding, eyeleting, and cutting at high speeds.

● Finishing Station, which with a reduced footprint offers users a machine that welds and sets eyelets in a single step.

● Evolve Welder, a flexible welding solution for companies needing to weld banners at high speed.

Manual, Semi-automatic, and Automatic Eyelet Equipment:

● HPS025 Hand Press, a portable self-piercing hand press for eyeletting PVC banners

● Queen, Speed Queen and Crossover Semi-Automatic Presses for applying eyelets

● Evolution, Autocross, and Multipress Automatic Presses suitable for a variety of materials

● Proprietary clear plastic and metal eyelets, manufactured in-house by PLASTGrommet

Media Roll Lifters and Storage Racks:

● JumboMAX, a new media roll lifter for Jumbo rolls up to 1,000kg

● RollMAX Lifter for large diameter heavy rolls up to 450kg

● Compact Lifter, a hydraulic media lifter for rolls up to 200kg

● Bull Rack MAX media storage rack for up to 600kg

● Jumbo Rolls Transporter, ideal for storing and transporting wide-format rolls

www.plastgrommet.com