By Sabine A Slaughter

Accelerating innovation, innovation cycles, and/or things and events leads to shorter and shorter cycles that decrease the value of things. This is especially true in our currently fast-living world.

I'd like to tell you a story:

A long time ago, machines and devices were mostly the same – only the skill of the operator made the difference. Great and greater products resulted from those that consumers and customers valued. Then came the time when more diverse machines and devices were available, resulting in operators specializing in certain fields. Thus, companies could offer differentiating products. Skilled expertise, skilled workers and skilled machine building took the main road. And even more diversification, specification resulted. Many companies were competing for the top spots. Many were investing into this or that machine or device as they increased their portfolio of different products. While the products were and are still valued, their value has been decreasing by the readily available products. Nearly everyone has been investing so much and in so many machines and devices that many could produce the same or likely products. Then came the new age of adding to this analogue and artly world a new type – digital production. First, only the daring invested. Soon more and more dared. New products were developed and those again, competing with products from traditional manufacturing, were held in high esteem. But the more companies invested not only in those new technologies but also kept abreast in the analogue world, the more competition went on. While competition up to a certain grade is good and encourages innovation, too much is too much. Meanwhile the overcapacity in the analogue world took on and sought the first casualties among the companies. More and more machines and devices emerged, not only for speciality production, but also for daily tasks. More and more products are of high value, though most, often when seeing a product, only the knowledgeable are able to tell the difference of the used production machine or process. The products have become a commodity, and everyday product. Only highly skilled workers that produce products with encompassing value-added features still catch the eye of the consumer and customer. And once again, I need to ask – have we reached the point of where too much is too much? No, not yet – because we still require highly skilled operators to produce those highly valued products. But that is too change if the industry has its own will. Manufacturers work on the next generation of machines – where operators act as "push buttoners" – just press a certain button and you get the desired result... So our highly valued products are once again becoming a commodity in the future. Specialised machines and devices that connect and talk to each other, that will produce certain products. And companies are once again expected to invest, adding to their already crowded park of machines, adding to the already established overcapacity whereby only the strong and daring will survive. So are we proving along the way that Darwin was right and only the strong survive, the ones that have adapted early enough and that continue to adapt to changing environments and markets? Well, we might have to agree with this as the printing industry changes.

However, does this only apply to the printing industry? Or the process of printing and manufacturing? I, myself, would say no. Each and every industry has to adapt to changing market environments, changing schedules and a faster and faster turning of their world. So what is new? Nothing really, but a lot in detail.

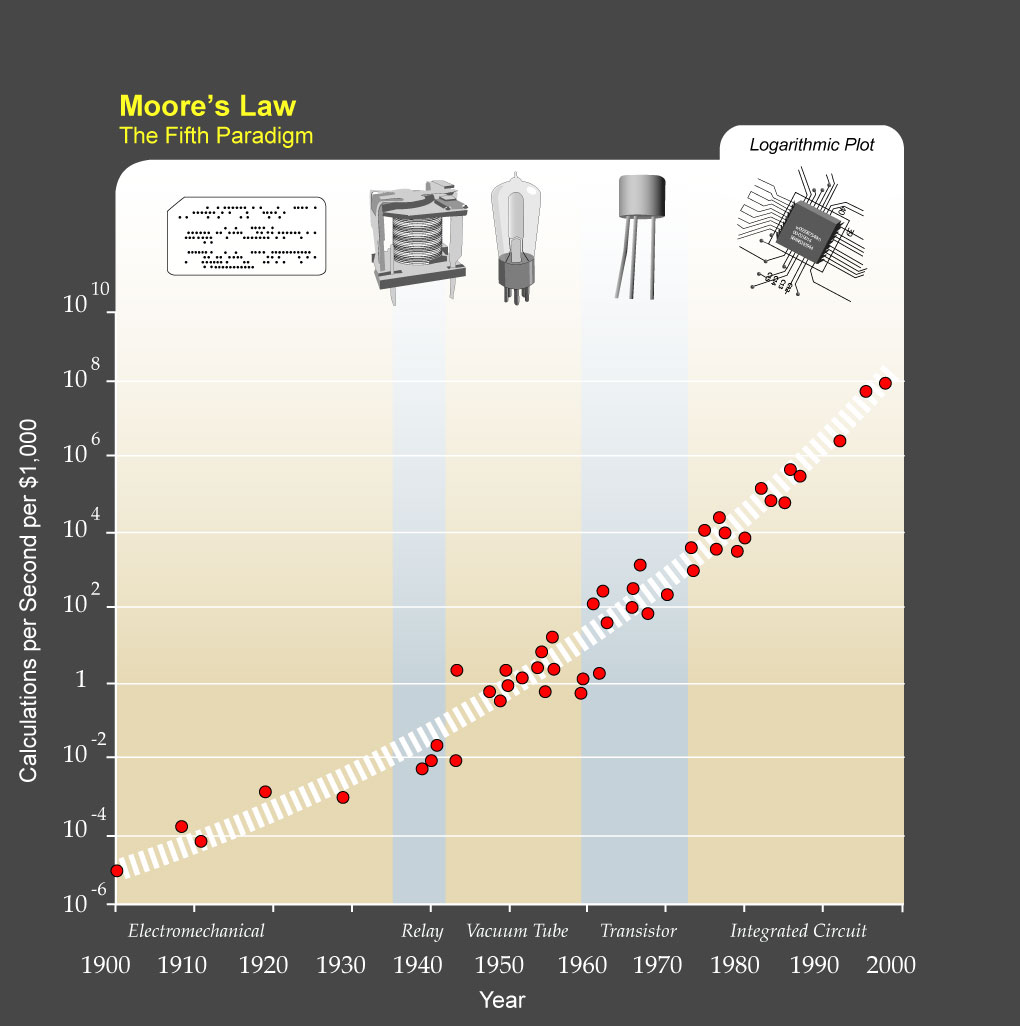

Manufacturers are inventing – faster and faster – according to Moore's law. This can be seen especially in the computing industry. Current innovation cycles in our own industry are short – considering 30, 50 years ago. And it has taken the manufacturers quite some time to get adapted to the current speed.

While for over 20 years, the innovation cycle has been determined by the "big four" in an Olympic cycle, covering the four directions of the wind, one of the four has been standing out and is still considered as the leading and foremost directional event. Many other events, local, regional, country-wise or even continent-wise have emerged. In the above little story, the word "machine" could also be exchanged with "event". And it still would hold true. But what would happen if this foremost leading event changes schedule? Would all the other participants, manufacturers, buyers, business customers etc. also change schedule, once again accelerating their innovation schedule to keep up? And if that would go along with a shortening of event time? Would they still be able to keep up in terms of attendance, in terms of investments? Would the buyer cast away their machinery faster thus buying more machines and devices in shorter cycles? Would this income for the manufacturer enable them to invent faster, to bring as much machinery to the now shorter event? Would the transport and build up costs be covered by the sales? Well, that's just some thoughts on which an answer is outstanding...

However, one thing would be sure: For faster invention cycles, the manufacturers will need more R&D budget that, in depressing and recovery times, is not as widely spread as it seems. And they need more workers and people, leading to higher employment numbers in those fields... That again will lead to higher costs that, in times when the word "restructuring" seems to be on the tongues of every manufacturer, is a "no-go".

But once again, it all means that in the end the consumer will value a product and pay a fair price and the business customer/buyer will invest in all these new inventions that have appeared now in a shorter cycle... And how likely is all this to happen and is everyone in the industry to act accordingly, just to prove that Moore's Law also applies to the printing industry?

In life all depends upon something and all belongs to everything. Every action triggers a reaction. So if the first requirement does not come true, how can the other requirements become true and foster a growing business environment in those challenging times?