Digital Printing is a relatively recent application for printing. The first digital printers were launched in the early 1990s and over the last 30 years have expanded to become a major segment of the printing industry.

Digital printing is a process in which a digital image is printed directly onto a media substrate using a combination of cyan, magenta, yellow, and black inks to create the finished product. As digital printing has grown, so has the wide variety of printers with varying degrees of resolution, image rendering, speed, and durability in today’s marketplace.

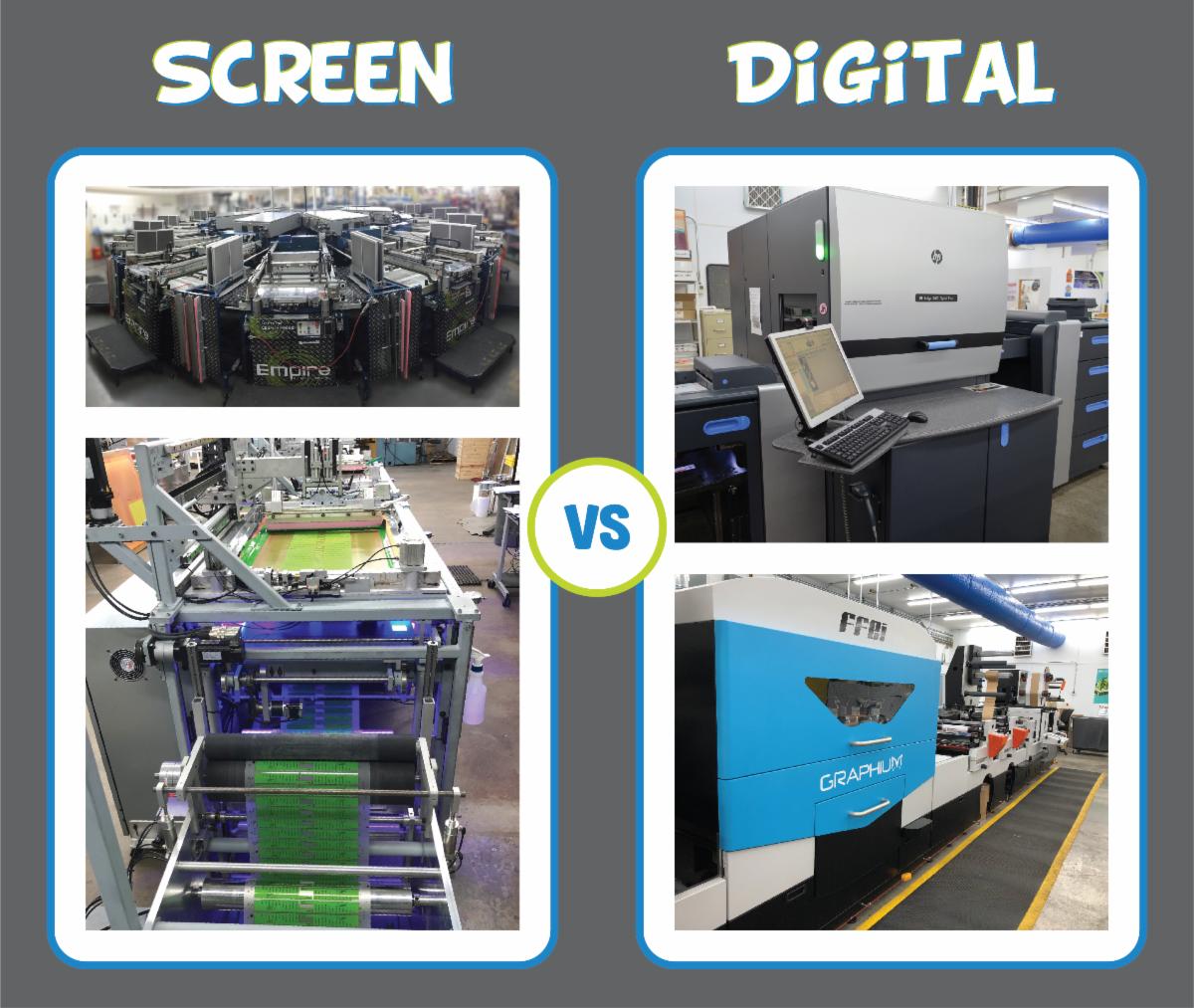

Screen printing on the other hand is the oldest form of print, dating back to China during the Song Dynasty (960-1279 AD) as a way of transferring designs onto fabrics. Over history, the equipment and technology have changed, but the overall concept of screen printing remains the same.

Screen printing is achieved by burning an image onto a screen mesh, creating a stencil. Using a squeegee, the ink is then pushed through the openings of the screen transferring the image onto the substrate below. A screen is needed for each color in the job, and each color is registered with one another to create the finished product.

In the early 1900s, screen printing revolutionized the commercial printing industry, as this process made it easy to print on a wide variety of materials, from fabric, metal, wood, and papers. With the onset of vinyl and plastic materials, the industrial label industry adopted this print method for its longevity and its durability to withstand the outdoor environment.

Comparing these two printing methods as a print buyer can be a challenge. Finding the best option for the desired end-use, while keeping costs at bay is the primary focus of print buyers. In today’s marketplace, more and more companies expect their brand identity to match across multiple media platforms, from websites to printed products, the customers want the image they see on the computer to match the image on their printed sheet.

At Empire Screen Printing they work with their customers to identify the right process for the product’s end-use. “As the printer, we work with our customers to find solutions and identify potential pitfalls so the outcome is understood and realized throughout the sales and production cycle. The key to this success is knowing and understanding the requirements of the product and what manufacturing process will yield the desired outcome at a fair price to the customer.” - Alexis Marsh - Empire Screen Printings VP of Operations

Traditional screen printing is the hardest output application, with greater tolerances, more variability, elaborate setups, and labor-intensive. Because of this process, the art goes through a vigorous prepress procedure, and sometimes the art needs to be altered to achieve a successful outcome. One element in screen printing is the addition of traplines. The standard trapline thickness is .02”, and is typically made with the darkest color (for example, black). The trapline hides two colors below it, which split the difference of the total trapline thickness. If the design has perfect registration, meaning more than one color makes up a graphic shape, then a trapline is needed to hold the integrity of the shape. Color order is an essential process for setting up art and knowing which colors can bleed under another color. For example, a red and green in the middle of a color spectrum has very little white in the color build. It’s mostly pigment, which is more transparent. When these colors overlap, the overlapping line can turn brown. The four-color process and ½ tone printing are more challenging and harder to control with screen printing and can result in moiré pattern, which occurs when the imaging dot interference with the screen mesh. Graphic line and font thicknesses must be a certain thickness to not fill in or disappear during the printing process. These changes are becoming less desirable with the onset of digital equipment.

Over time, customers see these undesirables and wonder what the alternative can be. Digital printing has changed the course of what the end-user is expecting out of their printed products. Digital provides a product that is similar to what they see on the computer and what’s on their corporate website.

Digital printing offers a process in which the customer’s artwork doesn’t need to be altered for the output. There are no plates, screens, or color-to-color registration issues. Digital is a less labor-intensive process and is perfect for 4-color process, variable data and serializing work, and is ideal for short to medium size runs and quick changeover jobs.

Over the last 10 years, digital printing has been growing and is expected to continue growing. According to www.marketsandmarkets.com, the digital printing market size is expected to increase from USD 24.8 billion in 2021 to USD 34.3 billion by 2026, at a CAGR of 6.7%. The demand for sustainable printing and developments in the packaging and textile industries are the main factors driving this growth.

Market share for screen printing was estimated at $1.8 billion in 2020 and is projected to reach a revised size of $5 Billion by 2027, growing at a CAGR of 16% according to Globe Newswire.

What does this mean for companies like Empire Screen Printing? “We must find ways to innovate and drive out costs or we will be irrelevant in the future,” says Empire Screen Printing’s President John Freismuth. “As market shifts, so does the research and development for this type of printing. More money is invested into the markets that are growing and that means digital equipment is currently a bigger influencer in the development process. How we utilize that technology for what we do can be an advantage in how we manufacture our product.”

A few questions need to be asked during the print-buying decision-making process: What is the desired use of the product? What material(s) are needed? Where is the product being used? Will it be Indoors or outdoors? What surface is it being applied to? What quantities are needed? How many colors are required to get the desired look, and how critical are these colors? How complex is the design?

As print buyers evaluate these questions, Empire’s sales team works to find solutions to reach the desired results and end-use of the product. Digital may seem like an easy alternative, but can also provide undesirable outcomes as well. Spot color match is limited when outputting on a CMYK digital device. High quantities and long-running jobs may not be the most cost-effective solution, and materials may need special coatings for the ink to adhere to the surface. Metallic inks are not available on most digital equipment, and the durability and longevity of the product can be reduced.

Some may expect that digital is a cheaper option, but higher ink costs and more consumables drive up the digital price. Digital uses less labor, as opposed to labor-intensive screen printing, and in some cases, speed can play a role in output. Digital can be ideal for small to middle quantity runs. For longer runs, screen printing may yield a quicker turn-time.

Knowing these pros and cons for each method, what has Empire Screen Printing provided their customers to combat these pitfalls in printing? Over 70% of Empire’s products are screen printed. They have created a niche in the market and fully expect it to continue to grow. They have streamlined the production process through lean principles and eliminated waste in the process that customers are not willing to pay for.

Empire has created standard work instructions and process controls for quick changeovers, implemented a Kanban system so work is available “just In time” for the next job. Screens are digitally imaged using a direct-to-screen imaging unit, and the screen reclaiming and developing process has been automated, cutting down on lead times throughout the entire process.

On press, Empire fabricated equipment to meet their needs with a highly intuitive registration system that more efficiently aligns color-to-color registration needs. Camera registration is utilized in printing and cutting operations. Moving equipment and operations closer together to provide one-piece flow opens the door for better communication, and quality becomes inherent to the process.

Empire is also revolutionary in its efforts to provide an environmentally-friendly screen printing process. One hundred percent of Empire’s screen printing manufacturing uses UV ink that has low VOCs, and 85% of that is cured using LED technology, which is 98% more energy-efficient with no ozone emissions. Empire can supply an environmental alternative to like-minded companies looking to reduce and monitor their carbon footprint.

Empire is not naive to the growing digital marketplace—They fully embrace this technology and have expanded their digital output capabilities.

“Providing an alternative to screen printing is essential to a diversified manufacturing facility. We will continue to improve and advance our screen printing while keeping an eye on the latest developments in digital equipment to continue to grow in both market spaces,” says Freismuth. “The world of digital equipment is rapidly changing. What wasn’t possible is now possible, and we have adapted to these changes to continue to offer our customers a product that meets their desired needs, whether it’s digitally output or screen printed.”

www.empirescreenprinting.com